Nanoceramic Powder Market To See Future Demand, Growth Opportunities, and Challenges by 2030

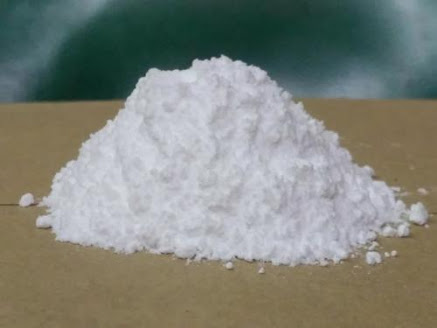

Nanoceramic powder refers to a type of ceramic powder that has particle sizes in the nanometer range, typically between 1 and 100 nanometers. Nanoceramic powders have unique properties compared to conventional ceramic powders due to their small size, such as increased surface area, higher reactivity, and improved mechanical, thermal, and electrical properties. Nanoceramic powders are produced through various techniques, such as sol-gel synthesis, hydrothermal synthesis, and ball milling. These techniques involve the synthesis and processing of ceramic precursors to produce nanoparticles of the desired composition, size, and morphology. Nanoceramic powders have a wide range of applications, such as in catalysis, fuel cells, sensors, biomedical implants, and electronic devices. They have also shown promising results in the development of high-strength and lightweight ceramic materials for structural applications, such as aerospace components and body armor. The global nanoceramic powder...