Nanoceramic Powder Market Up-To-Date Development Data And Industry Trends Forecast From 2022 to 2028

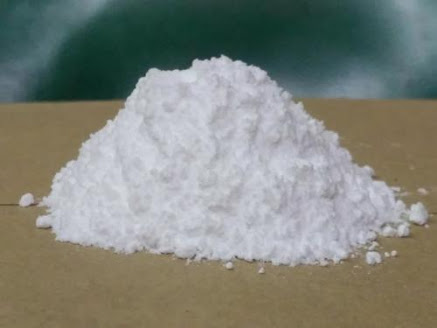

Nanoceramic powder refers to a type of ceramic material that is composed of tiny particles that are typically less than 100 nanometers in size. These powders are typically made using advanced manufacturing processes such as chemical vapor deposition, sol-gel synthesis, or high-energy ball milling. Nanoceramic powders are highly sought after for their unique properties, such as high strength, hardness, and resistance to wear and corrosion. They are used in a wide range of applications, including coatings, composites, electronics, and energy storage.

One of the key advantages of nanoceramic powders is their large surface area to volume ratio, which can enhance their reactivity and catalytic properties. They also have a high degree of homogeneity, which can improve their mechanical and thermal properties. However, the production of nanoceramic powders can be complex and expensive due to the advanced manufacturing techniques required. Additionally, the potential health and environmental risks associated with the production and handling of nanoparticles are a concern, and appropriate safety measures must be taken to minimize these risks.

The global nanoceramic powder market is expected to grow significantly in the coming years. This growth can be attributed to the increasing demand for nanoceramic powders in a wide range of applications, including automotive, aerospace, electronics, energy, and biomedical industries.

The automotive and aerospace industries, in particular, are expected to drive the growth of the nanoceramic powder market. Nanoceramic coatings can be used to improve the performance and durability of engine components and aircraft parts, leading to improved fuel efficiency and reduced maintenance costs.

The electronics industry is also a significant market for nanoceramic powders, as they can be used in the production of advanced electronic devices such as sensors, capacitors, and batteries. Nanoceramic powders are also used in the production of high-performance ceramics for applications such as cutting tools and bearings.

Geographically, the Asia-Pacific region is expected to be the largest market for nanoceramic powders due to the increasing demand from the automotive and electronics industries in countries such as China, Japan, and South Korea.

The global nanoceramic powder market size is expected to witness potential gains in the future and register a significant CAGR of 18% over the forecast period (2019 - 2027).

Major players operating in the gloabal nanoceramic powder market include, Innovnano, Synkera Technologies, Inc., and Nitto Denko Corporation

The automotive industry is expected to be a major driver of growth in the nanoceramic powder market. Nanoceramic coatings can improve the performance and durability of engine components, leading to improved fuel efficiency and reduced maintenance costs. In addition, nanoceramic coatings can enhance the aesthetics of automotive components, such as wheels and trim.

The electronics industry is also expected to drive growth in the nanoceramic powder market. Nanoceramic powders can be used in the production of high-performance electronic components, such as capacitors, sensors, and batteries. In addition, the increasing demand for smartphones, tablets, and other electronic devices is expected to boost the demand for nanoceramic powders.

The medical and healthcare industries are also expected to drive growth in the nanoceramic powder market. Nanoceramic powders can be used in the production of medical implants, such as dental implants and hip replacements. Nanoceramic coatings can also be used to improve the biocompatibility of medical devices.

The demand for nanoceramic powders is increasing rapidly in various industries, which is driving the growth of the nanoceramic powder market. The demand for nanoceramic powders is being driven by their unique properties, such as high strength, hardness, and resistance to wear and corrosion, which make them suitable for use in a wide range of applications.

One of the key factors driving the demand for nanoceramic powders is the increasing demand from the automotive industry. Nanoceramic coatings can be used to improve the performance and durability of engine components, leading to improved fuel efficiency and reduced maintenance costs. In addition, nanoceramic coatings can enhance the aesthetics of automotive components, such as wheels and trim.

The electronics industry is also driving the demand for nanoceramic powders. Nanoceramic powders can be used in the production of high-performance electronic components, such as capacitors, sensors, and batteries. The increasing demand for smartphones, tablets, and other electronic devices is also boosting the demand for nanoceramic powders.

The medical and healthcare industries are also driving the demand for nanoceramic powders. Nanoceramic powders can be used in the production of medical implants, such as dental implants and hip replacements. Nanoceramic coatings can also be used to improve the biocompatibility of medical devices.

In addition, the demand for nanoceramic powders is being driven by their use in the production of high-performance ceramics for applications such as cutting tools and bearings.

Nanoceramic powders have a wide range of applications in various industries. Some of the key applications of nanoceramic powders are:

Automotive Industry: Nanoceramic powders can be used to produce high-performance coatings for engine components, such as pistons, valves, and bearings. These coatings provide improved wear resistance and can help to increase fuel efficiency.

Electronics Industry: Nanoceramic powders are used in the production of advanced electronic components such as capacitors, sensors, and batteries. These powders can help to improve the performance and efficiency of these components.

Biomedical Industry: Nanoceramic powders can be used to produce medical implants such as dental implants, hip replacements, and bone screws. These powders are biocompatible and can improve the integration of the implant with the surrounding tissue.

Energy Industry: Nanoceramic powders can be used to produce high-performance materials for energy storage and conversion, such as fuel cells and batteries. These powders can help to improve the efficiency and performance of these devices.

Aerospace Industry: Nanoceramic powders can be used to produce coatings for aircraft components such as engines, landing gear, and structural parts. These coatings can help to improve the durability and reduce the weight of these components.

Textile Industry: Nanoceramic powders can be used to produce textiles with enhanced properties such as flame resistance, UV resistance, and antibacterial properties.

The use of nanoceramic powders in various industries offers several benefits. Some of the key benefits of using nanoceramic powders are:

Improved Performance: Nanoceramic powders offer improved performance characteristics, such as higher strength, hardness, and wear resistance, compared to traditional materials. This makes them suitable for use in high-performance applications where durability and performance are critical.

Increased Efficiency: The use of nanoceramic coatings can help to increase the efficiency of various components, such as engines, by reducing friction and improving heat transfer. This can lead to improved fuel efficiency and reduced maintenance costs.

Enhanced Aesthetics: Nanoceramic coatings can also enhance the aesthetics of various components, such as automotive parts, by providing a smooth, uniform finish and improving the color and gloss of the surface.

Biocompatibility: Nanoceramic powders are biocompatible and can be used in the production of medical implants without causing adverse reactions in the body. This makes them ideal for use in various medical and healthcare applications.

Environmental Benefits: Nanoceramic coatings can also offer environmental benefits, such as reducing the use of harmful chemicals in the production process and extending the life of components, which reduces the need for frequent replacements.

Cost Savings: The use of nanoceramic powders can help to reduce maintenance costs and extend the lifespan of components, which can result in significant cost savings over time.

Overall, the use of nanoceramic powders offers several benefits in terms of improved performance, increased efficiency, enhanced aesthetics, biocompatibility, environmental benefits, and cost savings. The increasing demand for high-performance materials is expected to continue to drive the growth of the nanoceramic powder market in the coming years.

.png)

Comments

Post a Comment