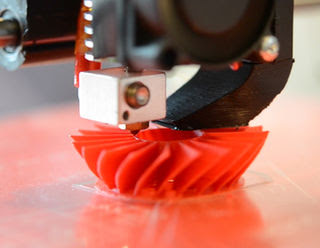

3D Printing Extrusion Materials Market Growth Accelerated by Increasing Adoption of 3D Printing in Various Industries

The opportunity in healthcare applications is driving the growth of 3D printingextrusion materials market. 3D printing finds significant usage in healthcare for manufacturing customized medical devices like dental crowns, prosthetics, and implants as well as bioprinting organs and tissues. This is due to advantages offered by 3D printing technology in developing accurate, reliable, and personalized solutions as per patient's requirement. The demand for biocompatible materials suitable for human implantation is increasing rapidly which is fueling the adoption of materials like PLA, PCL, and titanium. Moreover, significant research is ongoing worldwide to develop bioinks, scaffolds, and growth factors to build complex tissues and organs using bioprinting technology. The growing investments in developing advanced bioprinting solutions for clinical usage and 3D printed implants are contributing to the market growth of extrusion materials used for healthcare applications.

Porter’s Analysis

Threat of new entrants: The threat of new entrants in the 3D printing extrusion

materials market is moderate. High initial capital investments requirement for

building manufacturing facilities and developing extensive distribution

networks pose a barrier for new players. However, the growing demand and

advancements in technology provide opportunities for new entrants.

Bargaining power of buyers: The bargaining power of buyers in the 3D printing

extrusion materials market is high. The market is fragmented with presence of

numerous manufacturers providing buyers with options to choose from. This

enables buyers to negotiate on better pricing and terms.

Bargaining power of suppliers: The bargaining power of suppliers is moderate.

Raw material prices fluctuate frequently which could impact manufacturers'

profit margins. However, suppliers have limited bargaining power as they

operate in a competitive environment.

Threat of new substitutes: The threat of substitutes is low. 3D printing

extrusion materials have superior properties compared to traditional materials

used for similar applications. Product innovations are also reducing the threat

from substitutes.

Competitive rivalry: The competitive rivalry in the market is high owing to

presence of numerous regional and global players. Manufacturers differentiate

their products on the basis of material type, availability of customized

offerings, price, quality, and technical support.

SWOT Analysis

Strengths: Wide applications of 3D printing across industries such as

aerospace, automotive, medical, and consumer goods boosts market demand.

Advancements in material formulations improve printing efficiency and

application scope.

Weaknesses: High material costs and lack of technical expertise limits

adoption. Regulatory compliance and lengthy certification processes also pose

challenges.

Opportunities: Growing R&D investments in material development expand

market potential. Increasing collaborations with OEMs aid business expansion.

Threats: Volatility in raw material prices impacts profitability. Growing

environmental concerns regarding material disposal could lead to stringent

regulations.

Key Takeaways

The global 3D printing extrusion materials market is expected to witness high

growth over the forecast period on account of increasing demand from various

end-use industries such as aerospace, healthcare, and automotive.

Regional analysis: North America dominates the global market and is expected to

maintain its leading position throughout the forecast period. U.S. is the

largest market for 3D printing extrusion materials owing to presence of major

manufacturers and extensive R&D activities. Asia Pacific is projected to

witness fastest growth driven by rapid industrialization, competitive manufacturing

landscape, and growing adoption of additive manufacturing technologies in the

region.

.png)

Comments

Post a Comment