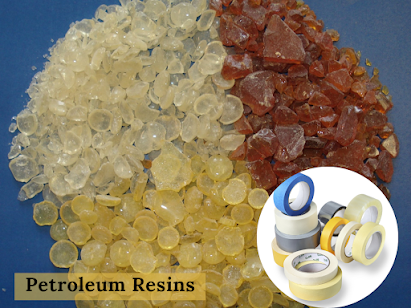

Petroleum Resins: Revolutionizing the Adhesive and Coating Industry

Petroleum resins, also known as hydrocarbon resins, are a class of thermoplastic polymers derived from petroleum or other hydrocarbon-based sources. These versatile compounds have found widespread applications in various industries, thanks to their unique properties and characteristics. From adhesives to coatings, rubber to plastic modifications, petroleum resins play a pivotal role in enhancing product performance and functionality.

Chemical Composition and Types:

Petroleum resins are produced through the polymerization of hydrocarbons obtained from the refining of crude oil. The exact composition varies depending on the manufacturing process and the intended application. However, they primarily consist of aliphatic, aromatic, or mixed aliphatic-aromatic hydrocarbons. Based on their chemical structure and properties, petroleum resins are classified into several types, including C5 resins, C9 resins, and hydrogenated resins.

Applications:

Petroleum resins have a diverse range of applications across various industries:

1. Adhesives and Sealants: Petroleum resins are widely used as tackifiers in adhesives and sealants. They improve the adhesive properties, increase cohesion, and enhance bond strength. Their compatibility with different polymers allows formulators to create adhesives for specific applications.

2. Coatings: In the coatings industry, petroleum resins act as key binders and modifiers. They improve the adhesion of coatings to substrates and provide resistance to weathering and chemicals. They are commonly used in paints, varnishes, and printing inks.

3. Rubber Modification: Petroleum resins are essential in the rubber industry for enhancing the properties of rubber compounds. They improve the tackiness of rubber and increase its strength and flexibility.

4. Plastics Modification: As plastic modifiers, petroleum resins enhance the performance of plastics by improving their clarity, heat resistance, and impact strength. They find application in a wide range of plastic products.

5. Tires: Petroleum resins play a critical role in the manufacturing of tires, where they act as tackifiers and reinforcement agents. They contribute to the tire's performance, durability, and handling.

6. Paper and Packaging: In the paper industry, petroleum resins are used as binding agents and modifiers to enhance paper coatings and packaging materials.

7. Printing and Labels: Petroleum resins are utilized in the printing industry to produce inks and labels with superior adhesion and printability.

8. Construction and Building Materials: They are employed in construction materials like concrete and asphalt modifiers, providing enhanced strength and durability.

Environmental Considerations:

While petroleum resins offer numerous benefits, concerns about their environmental impact exist. These resins are derived from non-renewable fossil fuels, raising questions about their sustainability. However, ongoing research and development are focused on finding alternative sources and greener production methods.

Conclusion:

Petroleum resins have become indispensable in many industrial applications due to their versatility, performance-enhancing properties, and cost-effectiveness. As technology and sustainability continue to evolve, the petroleum resin industry is likely to witness advancements aimed at reducing environmental impacts while meeting the demands of diverse applications across different sectors.

.png)

Comments

Post a Comment