Laminated Labels Market Size Estimate, Growing Industry Demands, Current Movements, and Business Opportunities From 2023 to 2030

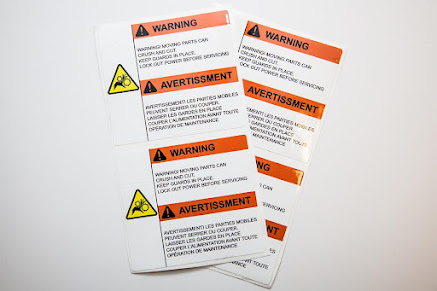

Laminated labels refer to labels that have a thin layer of protective material applied to their surface to enhance their durability and longevity. The protective layer, or laminate, can be made of various materials such as polyester, polypropylene, vinyl, or polyethylene, and is usually transparent or clear to allow the label's content to be visible. Laminated labels are commonly used in a variety of applications such as product labeling, inventory management, asset tracking, and identification labeling. They are ideal for use in environments where labels may be exposed to harsh conditions such as moisture, abrasion, chemicals, or UV light, as the lamination protects the label from damage and fading.

There are different types of laminated labels available, such as gloss, matte, or textured finishes, depending on the application's requirements. They can be custom printed with various colors, fonts, graphics, and sizes to meet specific labeling needs. Laminated labels are often used in industries such as manufacturing, logistics, healthcare, and retail, where durable and long-lasting labels are essential for efficient operations.

Key companies covered as a part of this study include Avery Dennison Corporation, Coveris Holdings S.A., CCL Label, Inc., Constantia Flexibles Group GmbH, Cenveo Corporation, Hub Labels, Inc., ImageTek Labelsm, SheetLabels.com, Langley Labels, and Reflex Labels

The increasing demand for laminated labels can be attributed to their durability, versatility, and aesthetic appeal. Laminated labels are used in various industries such as food and beverage, consumer goods, pharmaceuticals, cosmetics, and personal care products, where product safety and quality are essential.

The food and beverage industry is the largest end-use segment for laminated labels due to the stringent labeling regulations and the need for durable and moisture-resistant labels. The healthcare and pharmaceutical industries are also significant end-users of laminated labels for the labeling of medicines, medical devices, and diagnostic kits.

The demand for laminated labels is driven by various factors, including the increasing need for durable, moisture-resistant, and long-lasting labels across different industries. Laminated labels are widely used in various applications such as product labeling, identification labeling, asset tracking, and inventory management. The demand for laminated labels is expected to continue to grow due to the following reasons:

1. Regulatory Compliance: Regulatory bodies such as the FDA, EU, and other national and international organizations have stringent labeling requirements for various products, including food and beverages, pharmaceuticals, and medical devices. Laminated labels are preferred due to their durability and resistance to moisture, chemicals, and abrasion, making them ideal for complying with these regulations.

2. Branding: Laminated labels offer a premium look and feel, making them ideal for branding purposes. They can be customized with different finishes, textures, and colors to enhance the brand image and product appeal.

3. Product Safety: Laminated labels are essential for product safety, especially in the food and beverage industry. The lamination provides a protective barrier that prevents contamination and keeps the product fresh and safe for consumption.

4. E-commerce: With the growth of e-commerce, there is a need for durable and long-lasting labels that can withstand the harsh shipping and handling process. Laminated labels are ideal for e-commerce applications due to their durability and resistance to moisture, abrasion, and fading.

The laminated labels market offers numerous benefits to customers across various industries. Some of the key benefits of using laminated labels include:

1. Durability: Laminated labels are known for their durability and longevity. The protective layer of lamination enhances the label's resistance to moisture, chemicals, abrasion, and fading, making them ideal for use in harsh environments.

2. Customization: Laminated labels can be customized with different colors, fonts, graphics, and sizes to meet specific labeling needs. They can also be produced with various finishes such as gloss, matte, or textured, offering a wide range of customization options for branding and product labeling purposes.

3. Product Safety: Laminated labels play a crucial role in ensuring product safety, especially in the food and beverage industry. The lamination provides a protective barrier that prevents contamination and keeps the product fresh and safe for consumption.

4. Regulatory Compliance: Laminated labels are essential for regulatory compliance, especially in industries such as pharmaceuticals and medical devices, where labeling requirements are strict. The lamination provides an extra layer of protection that ensures the label's content remains legible and visible, even under harsh conditions.

5. Cost-Effective: Laminated labels offer a cost-effective solution for labeling needs. The longevity and durability of the label reduce the need for frequent label replacements, ultimately resulting in cost savings.

Overall, the laminated labels market offers several benefits to customers, including durability, customization, product safety, regulatory compliance, and cost-effectiveness. These benefits make laminated labels an ideal solution for various labeling needs across different industries.

.png)

Comments

Post a Comment